Pilot Updates: Magnesium Recovery

SEArcularMINE aims at securing European access to critical raw materials (CRMs) through the circular processing of saltwork bitterns.

As an element of this work, the team is exploring the recovery of Mg(OH)2 compounds from saltwork bitterns. To date, the EU imports magnesium that has been produced in carbon intensive processes around the world. The ability to derive such compounds from Europe’s abundant bittern resources in an environmentally friendly way would be extremely beneficial for European access to critical materials.

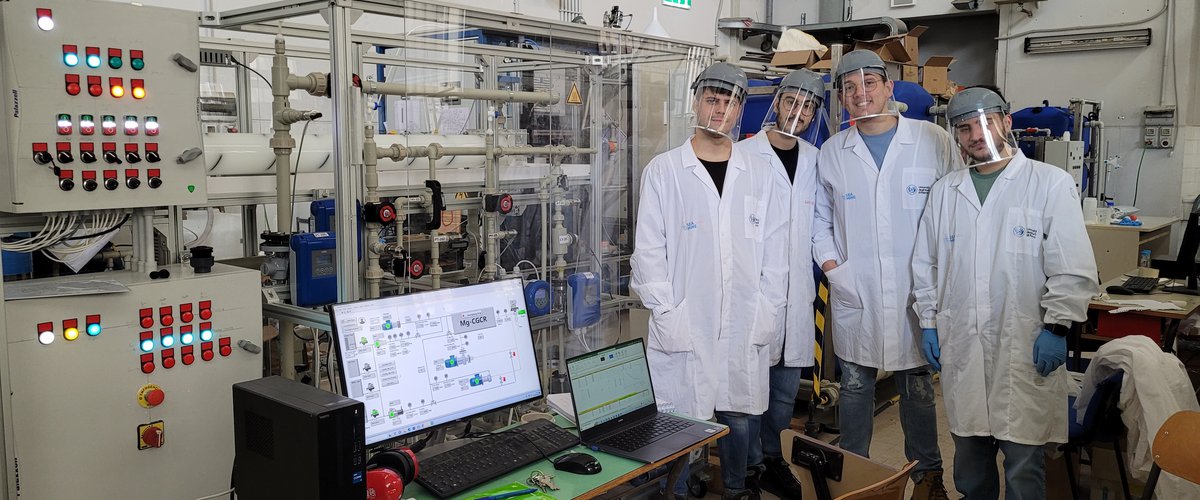

To explore this, the UNIPA and ResourSEAs teams have developed and tested different reactors, leading to an optimal and patented reactor (Mg-CGCR). The performance of this reactor is now being fully evaluated through testing in the UNIPA laboratories for the production of Mg(OH)2 compounds from real saltwork bitterns. Check out the photos below of the research team in action.

The results achieved so far are very encouraging: practically 100% of the magnesium in the bittern is recovered, and the resulting Mg(OH)2 has purity of over 99% and settling velocity 10 times faster than the reference reactors. Make sure to stay tuned for more updates on the SEArcularMINE pilot!

Interested in learning more? View this video for a more in-depth look at Magnesium, and the role it plays in the SEArcularMINE project.