Power Generation from Salinity Gradients

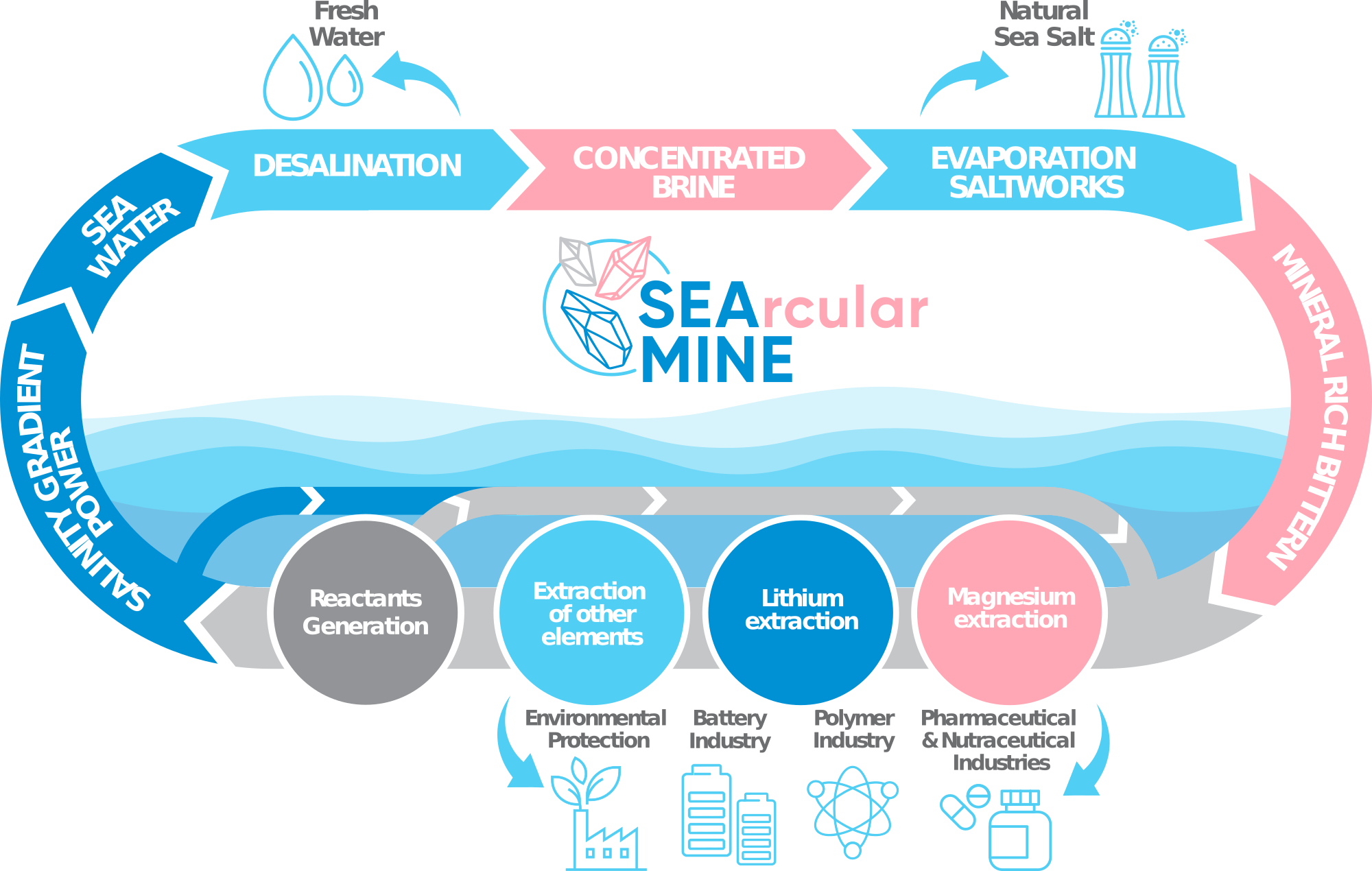

The process that SEArcularMINE is developing is fully circular, as highlighted in the figure below. The process begins with seawater that is used first to recover freshwater (through desalination) then sea salt (saltworks). Next, the process focuses on recovery of Magnesium (through crystallisation) and other trace elements (via absorption/desorption). The reactants required are also generated on-site through electrodialysis with bipolar membranes as a part of the process, leaving us at the end still with a concentrated brine.

In order to complete this circular process, the salinity gradient between the resulting concentrated brine and locally available brackish water are used in a Reverse electrodialysis (RED) process. RED is a membrane technology for the production of electricity through controlled mixing of solutions with different salt concentrations.

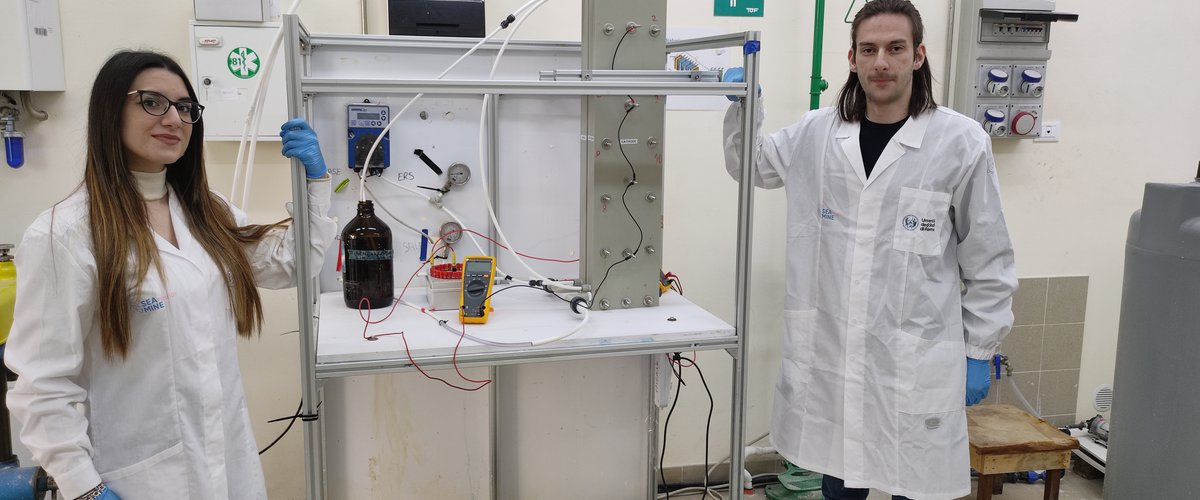

The RES and UNIPA teams are testing at a pilot scale the performance of the Reverse Electrodialysis (RED) technology at the SEArcularMINE conditions. The tests with real bitterns are progressing and the technology is performing as expected, generating the power levels that were foreseen by the advanced modelling tools. See the team working on utilising this technology below.